DTF transfers for hoodies and tees have emerged as a reliable, versatile option for decorating apparel, delivering bold colors with a soft hand and strong wash durability, and they work well across a range of fabrics, from blends to heavier knits. This introductory guide highlights why DTF transfers are popular for small shops and home studios, with practical tips that translate to consistent, scalable results, and it also outlines common pitfalls, estimated costs, and a workflow plan. You’ll learn the basics, including DTF transfer techniques and how to apply DTF transfers, along with practical steps for setup, design prep, and ink-jet to film workflows, and these steps are designed to reduce errors and increase repeatability across varying run sizes. Content covers choosing the right gear, from white-ink capable printers to heat presses, films, adhesives, and protective sheets, with emphasis on pre-press and pressure control, while recommendations account for budget, space, and safety. By the end, you’ll be ready to produce vibrant designs that withstand repeated washing while keeping feedback-friendly production cycles for small volumes, laying a solid foundation for more complex projects.

From a broader perspective, this is a film-to-fabric printing approach that uses a digital workflow to apply image-packed sheets to textiles with heat. Think of it as a dye-sub-like process that relies on a clear transfer film, pigment inks, and a precisely tuned heat press to lock in sharp details and color depth. The terminology shifts toward direct-to-film printing, pigment-on-fabric transfers, and garment decoration via hot-surface adhesion, which aligns with related concepts in modern apparel printing. The choice between this method and traditional screen printing depends on run size, color complexity, and budget, with film-based transfers excelling at short runs and multi-color designs while screen printing benefits large volumes and long-term durability. For shops, adopting a flexible workflow that emphasizes quick setup, consistent registration, and repeatable results is the key to profitability.

Frequently Asked Questions

What are DTF transfers for hoodies and tees, and why should I consider them?

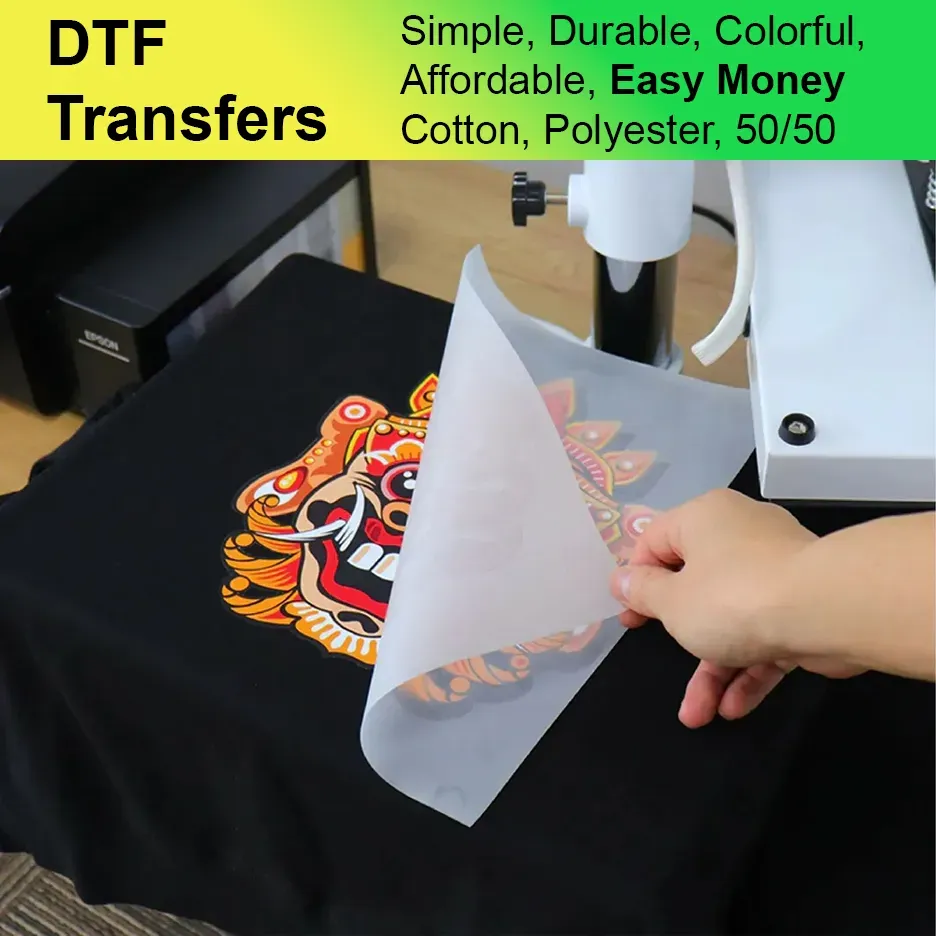

DTF transfers for hoodies and tees are printed-on-film designs that use pigment inks, a powder adhesive, and heat to transfer artwork onto fabric. They offer vibrant color on both light and dark fabrics, a soft hand feel, and are especially good for detailed images and small runs in a home studio or small shop.

How to apply DTF transfers for hoodies and tees?

Steps include printing the image on DTF transfer film with appropriate white ink, applying and curing the powder adhesive, pre-pressing the garment to remove moisture, aligning the transfer, pressing at the recommended temperature and time with even pressure, and finally peeling according to the film’s guidelines.

DTF transfer techniques for hoodies and tees: what should I know?

Key techniques include thorough garment pre-press, precise alignment, an appropriate underbase for dark fabrics, and ensuring full edge bonding. Use transfer boards or stable supports to prevent shifting, and practice on samples to minimize ghosting and edge lifting.

DTF vs screen printing for hoodies and tees: which is better for my project?

DTF transfers are ideal for small runs, complex multi-color designs, and fast setup, while screen printing shines for large-volume orders with simpler color schemes and high durability. Choose based on batch size, color count, design complexity, and budget.

What are the best heat press settings for DTF transfers on hoodies and tees?

Follow the transfer material’s guidelines. Typical practice uses moderate to high pressure for about 10–20 seconds, with temperature set per the ink and film specifications. Ensure proper curing of the adhesive, pre-press garments to remove moisture, and adjust for fabric thickness and ambient conditions.

| Aspect | Key Points |

|---|---|

| What are DTF transfers | Direct to film: pigment inks on film, powder adhesive, cure, then transfer to fabric. Benefits include a wide color gamut, fine detail, crisp images, strong color coverage on light/dark fabrics, a soft hand, and a forgiving process for gradients. Suitable for in-house production with lower setup costs than traditional screen printing. |

| Setup for hoodies vs tees | Requires a desktop printer with white ink, a heat press, DTF powder adhesive, and transfer film. Hoodies need longer dwell times and pre-press to reduce moisture/wrinkles; tees cure quickly and benefit from consistent platen pressure. |

| Key gear and materials | Printer with white ink capability; DTF transfer film and PET clear films; DTF powders; curing method (oven/flash/dedicated); heat press with temp/pressure control; Teflon/silicone sheets; tape, scissors, lint roller; foam rollers or brayers. |

| Bootstrapping a reliable workflow | Start with clean, dry garments; pre-press to remove moisture and wrinkles; align design with tape; ensure consistent placement; heat properly without scorching; flatten seams on hoodies; tees require flat surfaces and even pressure. |

| Design considerations | High resolution/color depth; proper underbase for dark fabrics; bleeds/margins for heat press margins; standard placements for consistency; use vector elements for text; optimize bitmaps to avoid banding. |

| From design to finished transfer (steps) | 1) Design/preflight 2) Print on transfer film 3) Apply powder 4) Cure powder 5) Prepare garment 6) Transfer and cure on fabric 7) Peel and inspect 8) Post press (optional). |

| Tips for best results | Proper garment prep; follow manufacturer heat settings; monitor hand feel; inspect edge integrity; practice on samples before batch runs. |

| Common issues & troubleshooting | White edge/halo: ensure film alignment and powder adhesion; fading color: verify cure time/temperature; cracking at seams: adequate pre-press and avoid excessive heat in curves; ghosting/misregistration: stable alignment and transfer boards. |

| DTF transfers vs screen printing | DTF enables rapid setup, lower minimums, vibrant results on many fabrics, and easy customization for small runs. Screen printing is cost-efficient for large-volume runs with simple color schemes. DTF suits multi-color/gradients; screen printing suits large batches with consistent color. |

| Care, durability, and care tips | Wash inside out in cold/warm water, avoid harsh detergents, tumble dry low or line dry. Ensure proper curing; with correct care, DTF transfers resist cracking or fading over many washes. |

| Cost considerations and scalability | Lower startup costs for small operations; cost per transfer depends on film, adhesive, ink, and printer maintenance. Scale by batching, optimizing pre-press, dwell times, and cure times; plan for consumables and replacement parts. |

| Frequently asked questions | Fabric compatibility (test on blends/heavy fabrics); white ink printer necessity for light-on-dark designs; pre-press recommended for adhesion and alignment. |